Wing Slots And Slats

- Winged chain link fence slats provide increased privacy over most other slats. These self-locking double-wall fence slats (no locking channels needed) combine the proven quality and durability of our standard slats with unique “wings” for extra screening and security.

- This shows how open the slot is compared to the regular 701 fixed slats, and also how the wing leading edge is sharp, and the slot is much more streamlined, so much less drag when the slats are deployed. The retractable slats are in two portions on each side.

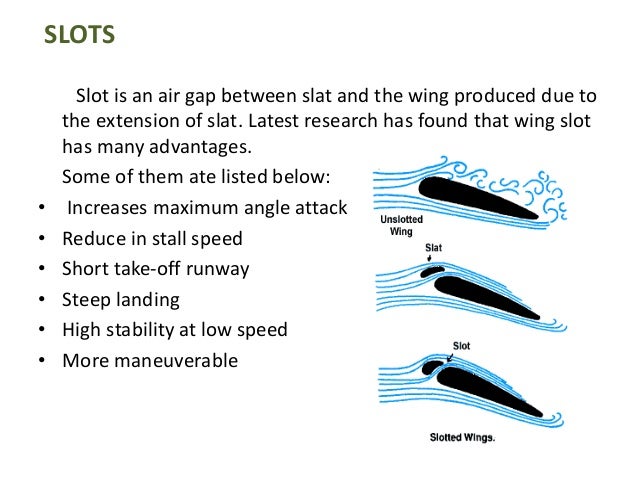

- Airfoil camber, flaps, slots, slats & drag.

- Slats perform the same function as flaps (that is, they temporarily alter the shape of the wing to increase lift), but they're attached to the front of the wing instead of the rear. Pilots also deploy them on takeoff and landing. Pilots have to do more than guide a plane through takeoff and landing though.

Slats are extendable, high lift devices on the leading edge of the wings of some fixed wing aircraft. Their purpose is to increase lift during low speed operations such as takeoff, initial climb, approach and landing.

Slats are aerodynamic surfaces on the leading edge of the wings of fixed-wing aircraft which, when deployed, allow the wing to operate at a higher angle of attack. A higher coefficient of lift is produced as a result of angle of attack and speed, so by deploying slats an aircraft can fly at slower speeds, or take off and land in shorter distances. They are usually used while landing or performing maneuvers which take the aircraft close to the stall, but are usually retracted in normal flight to minimize drag. They decrease stall speed.

Slats are one of several high-lift devices used on airliners, such as flap systems running along the trailing edge of the wing.

Wing Slots And Slats Home Depot

Types[edit]

Types include:

- Automatic

- The spring-loaded slat lies flush with the wing leading edge, held in place by the force of the air acting on them. As the aircraft slows down, the aerodynamic force is reduced and the springs extend the slats. Sometimes referred to as Handley-Page slats.

- Fixed

- The slat is permanently extended. This is sometimes used on specialist low-speed aircraft (these are referred to as slots) or when simplicity takes precedence over speed.

- Powered

- The slat extension can be controlled by the pilot. This is commonly used on airliners.

Operation[edit]

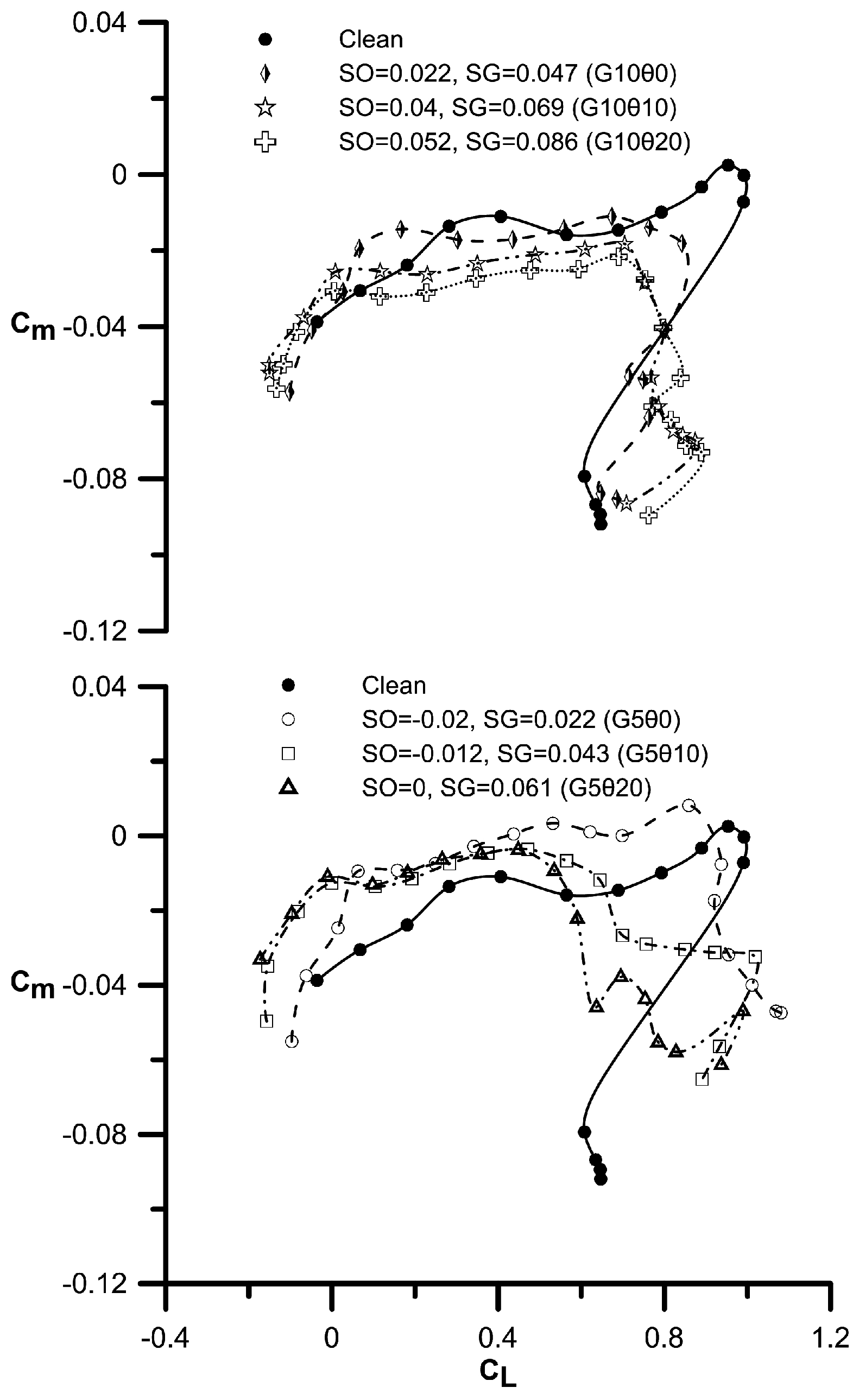

The chord of the slat is typically only a few percent of the wing chord. The slats may extend over the outer third of the wing, or they may cover the entire leading edge. Many early aerodynamicists, including Ludwig Prandtl, believed that slats work by inducing a high energy stream to the flow of the main airfoil, thus re-energizing its boundary layer and delaying stall.[1] In reality, the slat does not give the air in the slot a high velocity (it actually reduces its velocity) and also it cannot be called high-energy air since all the air outside the actual boundary layers has the same total heat. The actual effects of the slat are:[2][3]

- The slat effect

- The velocities at the leading edge of the downstream element (main airfoil) are reduced due to the circulation of the upstream element (slat) thus reducing the pressure peaks of the downstream element.

- The circulation effect

- The circulation of the downstream element increases the circulation of the upstream element thus improving its aerodynamic performance.

- The dumping effect

- The discharge velocity at the trailing edge of the slat is increased due to the circulation of the main airfoil thus alleviating separation problems or increasing lift.

- Off the surface pressure recovery

- The deceleration of the slat wake occurs in an efficient manner, out of contact with a wall.

- Fresh boundary layer effect

- Each new element starts out with a fresh boundary layer at its leading edge. Thin boundary layers can withstand stronger adverse gradients than thick ones.[3]

The slat has a counterpart found in the wings of some birds, the alula, a feather or group of feathers which the bird can extend under control of its 'thumb'.

History[edit]

Slats were first developed by Gustav Lachmann in 1918. The stall-related crash in August 1917 of a Rumpler C aeroplane prompted Lachmann to develop the idea and a small wooden model was built in 1917 in Cologne. In Germany in 1918 Lachmann presented a patent for leading-edge slats.[4] However, the German patent office at first rejected it as the office did not believe the possibility of postponing the stall by dividing the wing.

Wing Slots And Slats Doors

Independently of Lachmann, Handley Page Ltd in Great Britain also developed the slotted wing as a way to postpone the stall by delaying separation of the flow from the upper surface of the wing at high angles of attack, and applied for a patent in 1919; to avoid a patent challenge, they reached an ownership agreement with Lachmann. That year an Airco DH.9 was fitted with slats and test flown.[5] Later, an Airco DH.9A was modified as a monoplane with a large wing fitted with full-span leading edge slats and trailing-edge ailerons (i.e. what would later be called trailing-edge flaps) that could be deployed in conjunction with the leading-edge slats to test improved low-speed performance. This was later known as the Handley Page H.P.20[6] Several years later, having subsequently taken employment at the Handley-Page aircraft company, Lachmann was responsible for a number of aircraft designs, including the Handley Page Hampden.

Licensing the design became one of the company's major sources of income in the 1920s. The original designs were in the form of a fixed slot near the leading edge of the wing, a design that was used on a number of STOL aircraft.

During World War II, German aircraft commonly fitted a more advanced version of the slat that reduced drag by being pushed back flush against the leading edge of the wing by air pressure, popping out when the angle of attack increased to a critical angle. Notable slats of that time belonged to the German Fieseler Fi 156Storch. These were similar in design to retractable slats, but were fixed and non-retractable. This design feature allowed the aircraft to take-off into a light wind in less than 45 m (150 ft), and land in 18 m (60 ft). Aircraft designed by the Messerschmitt company employed automatic, spring-loaded leading-edge slats as a general rule, except for the Alexander Lippisch-designed Messerschmitt Me 163BKomet rocket fighter, which instead used fixed slots built integrally with, and just behind, the wing panel's outer leading edges.

Post-World War II, slats have also been used on larger aircraft and generally operated by hydraulics or electricity.

Research[edit]

Several technology research and development efforts exist to integrate the functions of flight control systems such as ailerons, elevators, elevons, flaps, and flaperons into wings to perform the aerodynamic purpose with the advantages of less: mass, cost, drag, inertia (for faster, stronger control response), complexity (mechanically simpler, fewer moving parts or surfaces, less maintenance), and radar cross-section for stealth. These may be used in many unmanned aerial vehicles (UAVs) and 6th generation fighter aircraft. One promising approach that could rival slats are flexible wings.

In flexible wings, much or all of a wing surface can change shape in flight to deflect air flow. The X-53 Active Aeroelastic Wing is a NASA effort. The adaptive compliant wing is a military and commercial effort.[7][8][9]

See also[edit]

References[edit]

- ^Theory of wing sections, Abbott and Doenhoff, Dover Publications

- ^High-Lift Aerodynamics, A.M.O. Smith, Journal of Aircraft, 1975

- ^ abHigh-Lift Aerodynamics, by A. M. O. Smith, McDonnell Douglas Corporation, Long Beach, June 1975Archived 2011-07-07 at the Wayback Machine

- ^Gustav Lachmann - National Advisory Committee for Aeronautics (November 1921). 'Experiments with slotted wings'(PDF). Retrieved 2018-10-14.

- ^Handley Page, F. (December 22, 1921), 'Developments In Aircraft Design By The Use Of Slotted Wings', Flight, XIII (678), p. 844, archived from the original on 2012-11-03 – via Flightglobal Archive

- ^F. Handley Page 'Developments In Aircraft Design By The Use Of Slotted Wings'Archived 2012-11-03 at the Wayback MachineFlight, December 22nd 1921, photo page 845 of converted D.H.4 for testing of slotted wings

- ^Scott, William B. (27 November 2006), 'Morphing Wings', Aviation Week & Space Technology, archived from the original on 26 April 2011

- ^'FlexSys Inc.: Aerospace'. Archived from the original on 16 June 2011. Retrieved 26 April 2011.

- ^Kota, Sridhar; Osborn, Russell; Ervin, Gregory; Maric, Dragan; Flick, Peter; Paul, Donald. 'Mission Adaptive Compliant Wing – Design, Fabrication and Flight Test'(PDF). Ann Arbor, MI; Dayton, OH, USA: FlexSys Inc., Air Force Research Laboratory. Archived from the original(PDF) on 22 March 2012. Retrieved 26 April 2011.

External links[edit]

| Wikimedia Commons has media related to Leading-edge flaps. |

Wing Slat Fence Slat

When you need increased privacy for your chain link fence, Wing Slat is the answer - chain link privacy slat. With the proven quality and durability of our standard slats plus unique 'wings' for extra screening and security, these slats are self-locking - no channels are needed! Includes a rigid, flat tubular body, with 'legs' inside for extra support. Flexible and resilient wing portions are positioned on each side of the slat body. Serrations are added to the wings for easier installation and locking power.

Instructions for measuring the diamond size for chain link fence.

Click here to read why there isn't a privacy slat for diamond sizes larger than 2 inches.

How do I know what fence slat will fit into my fence?

Shipping Included in the Price

(48 contiguous states only - additional shipping for Hawaii and Alaska)

When comparing prices, make sure shipping is included in the price.

Coverage: Each bag contains 82 pieces. For a 2 inch diamond, each bag will cover approximately 10 linear feet of fence (depends on how tight your fence is stretched – the average chain link fence with a 2 inch diamond has 41 diamonds for every 10 linear feet of fence).

Warranty: Manufacturer's 25-year limited pro-rata warranty.

Notes: 3' and 7' slats will take approximately 3 to 4 weeks for delivery (special order - non returnable).

Depending on your location and quantity ordered, there may be an extra shipping fee for eight foot and higher Wing Slats. If there is an extra fee, you will be contacted after your order is received.

Vinyl Coated Chain Link Fence Notes: Installing the Wing Slat in some vinyl coated colored chain link fence may be more difficult to install depending on the diamond size, gauge of wire and how tight the fence is stretched. When sliding the slat down into the chain link fence, the wing portion on the slat may cause friction against the vinyl coated chain link fence making it difficult to insert. We have had hundreds of customers install this slat with vinyl coated chain link fence without a problem, but there have been a few who could not get the slat to insert.

Made in the USA: Be aware of some non-USA made fence slats that may fade and discolor. Our slats made of virgin High Density Polyethylene (HDPE) are made in the USA and have UV inhibitors (UV resistant color concentrates) to add color protection and guard against cracking, chalking, and fading in the sunlight.

Durability: Our slats are also resistant to severe weather conditions, salt water, sand, road dirt, most acids, alcohol, alkaline, ammonia, petroleum distillates, and common environmental pollutants.

The entire slat is wider than most providing very good privacy. The picture on the left shows a top view looking down at the Wing Privacy Fence Slat.

Wing Slat with Bottom Locking Runner

Customers fence diamond was larger than 2' so a bottom locking runner was added.

I finished the fence. I am pleased with it.....not bad for a 74 year old lady. Vivienne B.

| Beige | Black | Brown | Green | White | Redwood | Sky Blue | Royal Blue | Gray |

These fence slat colors are approximations only, please refer to actual color samples for final matching.